Many of us are entering a period of social distancing. So we thought we’d share “a day in the life of” a number of our key staff, who are keeping Interpump Fluid Solutions running. Today, we meet UK Sales Manager, Keith Greenleaf.

A Day In The Life Of Keith Greenleaf

Keith, what time do you get up on a typical work day?

A change of life. A change of discipline for us all. With this week being one of the most rollercoaster and challenging times in our lives, I struggle to call these present days typical. Currently I wake up at 6.30am and normally I’m in front of the laptop by 7.30am

Can you give an example of where you might be heading?

Unfortunately and as with the majority of the country, working from my home office is now becoming the norm, utilising our remote access and direct links to all our facilities. Our warehouse / production facilities and mobile service are fully open, providing a diversity of products and services to support UK mainline services in these times of need. We our constantly monitoring the government guidelines and continuing to provide the upmost safety procedures and equipment to all our first-class dedicated staff and customer.

What kind of customer contact are you having at the moment?

In light of the current unprecedented times my day is spent communicating with our customers on the telephone and emails and increasingly incorporating social media. Having such a diversity of customers, including end users, stockists, distriutors, OEM and manufacturing, to name just a few, ongoing daily communication is a key.

How are customers’ sites looking and feeling at the moment?

Having not visited customers over the last week, but spoken with many, the general consensus I feel is uncertainty, but a large degree of togetherness.

What’s the best part of doing a job like this?

Normally meeting such a diverse range of customers and discussing their requirements and providing the appropriate solutions. This has now become even more important in communicating with our customers and staff.

How does the rest of your day shape up?

Working from home has forced me into totally different disciplines; setting out timescales, tasks and goals throughout the day.

What are the biggest challenges you are facing at work right now?

Our challenges are changing by the day. Currently we have a highly motivated and dedicated staff with the usual stock available for next day delivery.

How do you see Interpump Fluid Solutions developing in the coming months and year?

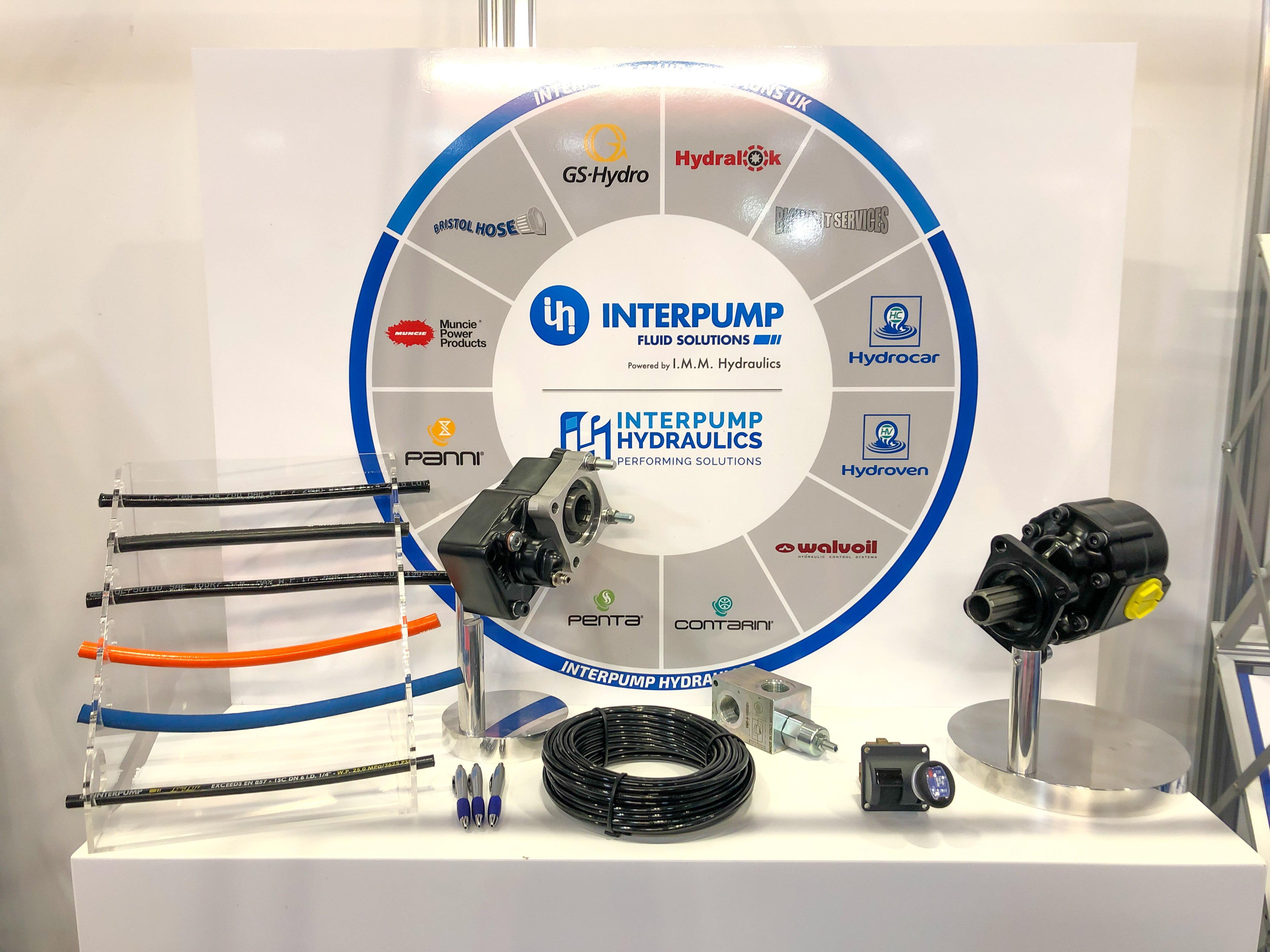

We have a unique opportunity and are strategically situated in the marketplace, having such a diverse product range, combined with a high level of investment to be able to provide first-class total fluid solutions in the months and years to come.

From your perspective, what are the big opportunities?

Working closely with our key stockist and distributor’s to enhance their access to our full product range.

If you could name one thing you most enjoy about your job?

I’m always meeting different people.

What kind of time do you clock off at the end of a typical day?

Currently the working day continues way into the evening.

How do you balance your life outside of work with a demanding job like this?

During normal times, I am a level four football referee and normally I’m out every Saturday. Having played football for many years, this has given me the opportunity to give something back to the sport. I also spend quality time with my family.

What’s your Top Tip for working through these current challenging times?

Stay focused, disciplined, proactive, optimistic and look after everyone. Hopefully out of diversity, something positive will come.