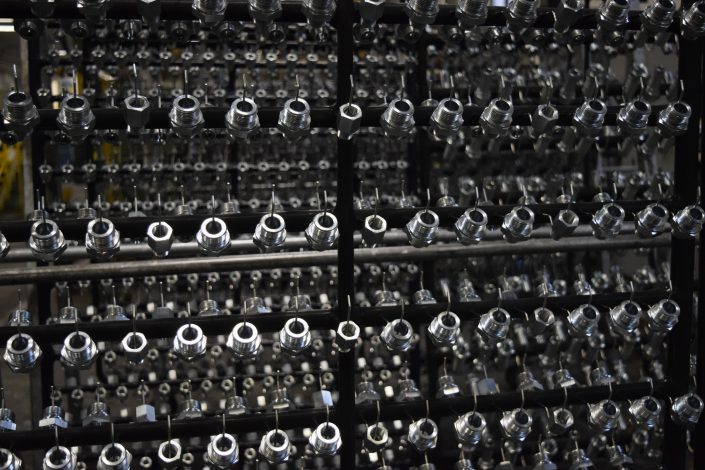

Today Antonio Orlando, our technical manager of FGA SRL, explains what happens in our galvanic plant, where we galvanise our fittings and adapters.

<< FGA is located a few kilometres from our headquarters in Atessa, Italy. It opened in 2004 and soon grew through the investment of significant financial resources, expanding the range of processes available.

The FGA has a laboratory dedicated to analysing the concentrations of the galvanic baths, constantly monitoring all the process parameters.

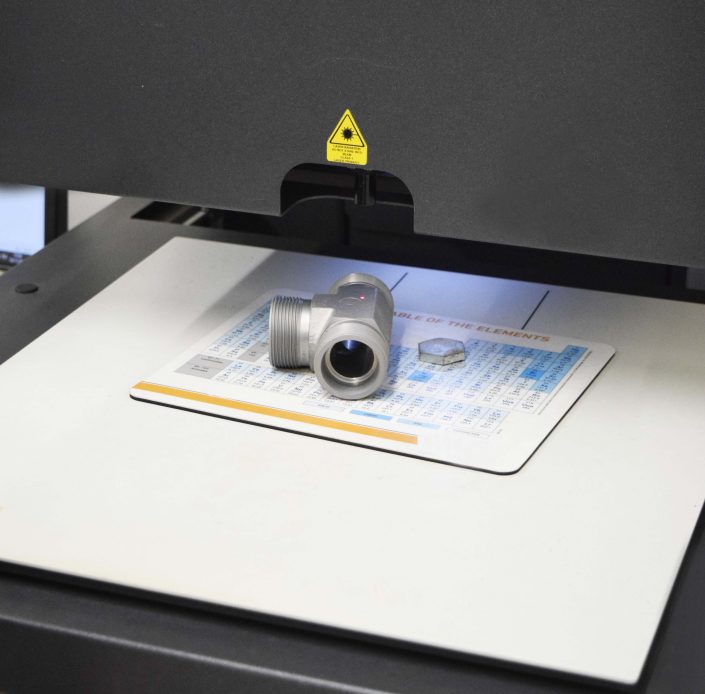

These processes consist of a saline mist to carry out accelerated corrosion tests according to UNI EN ISO 9227: 2017, a modern X-Ray thickness gauge and a Galvatest for the control of additives in the galvanic baths.