Hel Performance : 20 years with Hydralok hydraulic machines

Based just outside of Exeter, in the South West of the UK, Hel Performance’s headquarters boasts an impressive hose assembly centre, with eight Interpump Fluid Solutions Hydralok H32 electric machines, including the latest Hydratouch model. With these machines in constant use and hundreds of customer order being despatched on a daily basis, it is key that production runs smoothly and efficiently. Hel Performance products are now available in over 72 countries around the world, covering the five continents of Europe, America, Africa, Asia and Australasia.

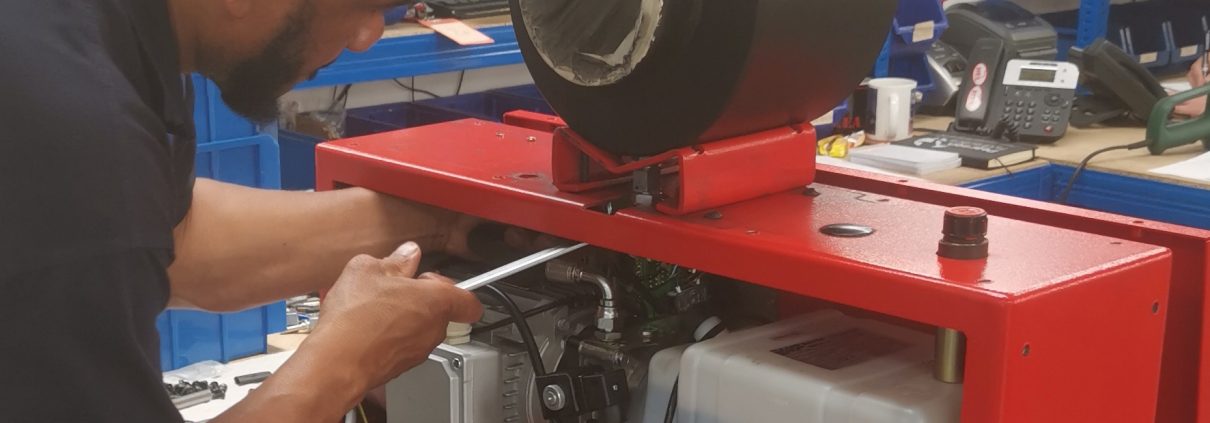

Working collaboratively over the last 20 years, the Hydralok team at Interpump Fluid Solutions have devised with Hel Performance a machine support programme that ensures all staff at Hel Performance are fully trained in how to keep their machines in tip top condition, at the same time that each machine is regularly serviced by the Hydralok team.

Both Hel Performance and the Hydralok team at Interpump Fluid Solutions, as UK manufacturers, have a history and reputation of innovation and quality:

Hel Performance

First fully-swaged brake line in the UK

Only aftermarket brake line manufacturer in the UK that machines all of its own mainline brake fittings in stainless steel in-house on their Star CNC Sliding Head lathes. Hel Performance have their own in house machine shop to manufacture their mainline fittings and brake callipers. They have invested in an impressive CNC department: 12 x Star SR20J machines (20mm bar capacity) 1 x Star SR12 (12mm bar capacity) and have recently added a Star SR38 (38mm bar capacity, ) 2 x Brother S700X1 and 1 x Brother M140X2. They also have a 3D Printer on site (ABS modelling) for quick prototype parts

First manufacturer in the industry to offer a PVC cover applied during the hose manufacture to protect the bodywork and paint of the vehicle

First manufacturer in the world to offer coloured stainless steel fittings as a safe replacement to dangerous coloured aluminium brake line fittings

World’s first mountain bike brake line kit that includes all fittings required to manufacture a hose for any current system.

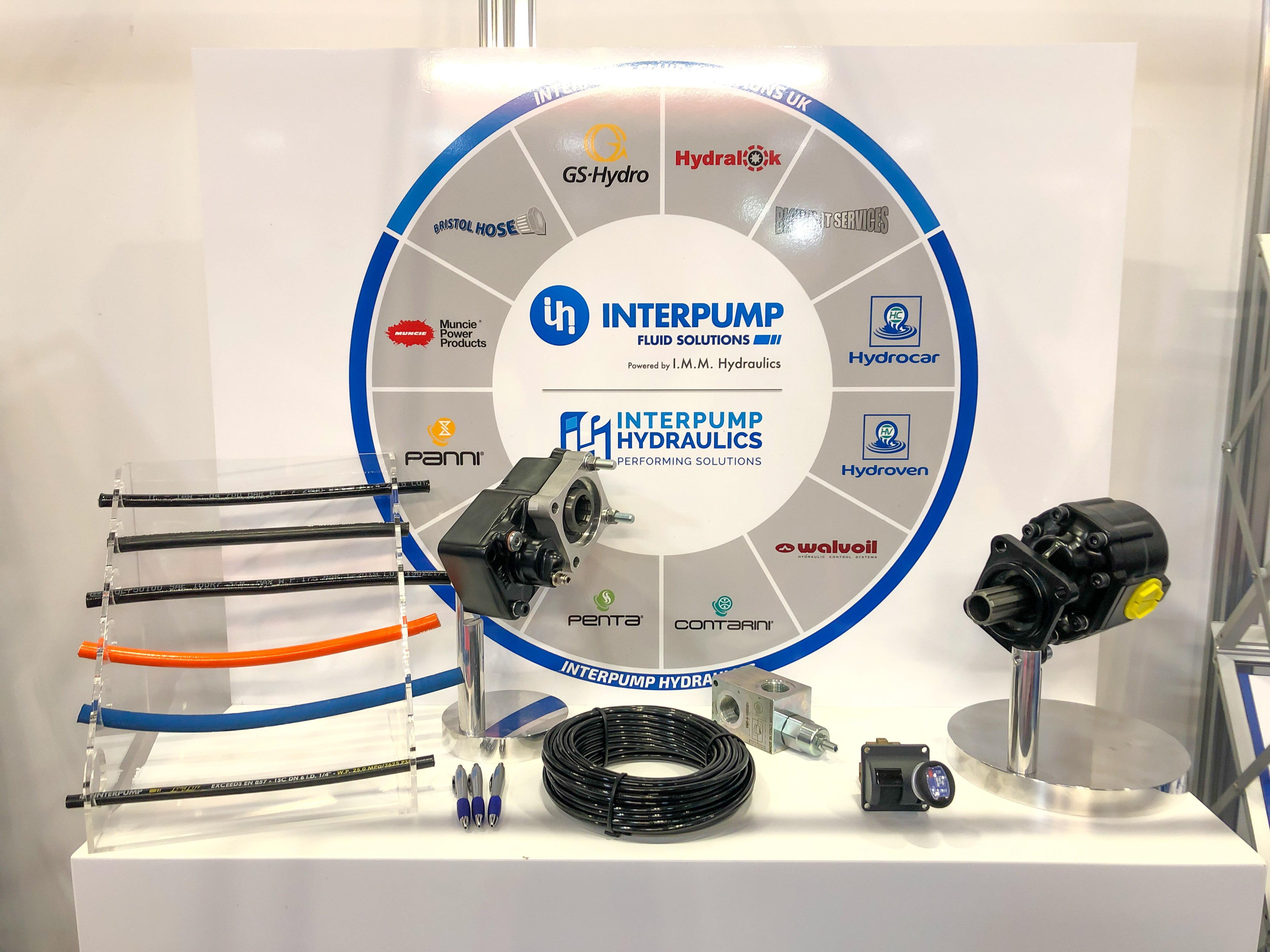

Hydralok team at Interpump Fluid Solutions

History of leading design and manufacture of manual swaging machines

Development of 12v centrifugal hose-skiving machine for mobile hose repair fleets

One of the first manufacturers to offer touch screen control on service level swaging machines

Working together continues with the Hydralok team at Interpump Fluid Solutions designing custom swaging collets and dies for a range of hydraulic machines to suit HEL Performance brake line fittings: the Compak, H25 Mini, H25MM, H32 electric machines including the Hydratouch range; to ensure both a functional and safe swage that in this demanding marketplace, also looks great. These machines and custom dies are sold exclusively via Hel Performance to their ever-expanding global network of dealers as part of their complete customer focused solution, enabling dealers to manufacture any brake line kit on site, at their convenience. This is especially important when working in a different time zone or when dealers are offering on-site support at automotive events.

For more information about Interpump Fluid Solutions Hydralok products, please visit https://www.interpumpfluidsolutions.com/uk/products/machines/

For more information about Hel Performance, please visit https://auto.helperformance.com