Our core business is certainly the production of hoses, but our offer is much wider: fittings, adapters, machines and of course the flanges that we’re talking about today. Thanks to Pierlugi D’Alonzo, product manager of GS-Hydro and stainless steel fittings division, we find out exatly what these GS components are and why they are part of the integrated rigid system.

Our core business is certainly the production of hoses, but our offer is much wider: fittings, adapters, machines and of course the flanges that we’re talking about today. Thanks to Pierlugi D’Alonzo, product manager of GS-Hydro and stainless steel fittings division, we find out exatly what these GS components are and why they are part of the integrated rigid system.

Following the interview.

What are GS Components?

We are talking about flanged connections for seamless rigid pipes, which find the main application in hydraulics, where the high pressures, together with the characteristics of the application, place stringent requirements on pipe connections.

They are represented by a wide range of combinations that can be summarized in three main systems: the Retain Ring and 37º Flare Flange systems are used for high pressure connections and the 90º Flare Flange connection for low pressure applications.

The range of use of entire line can be so very large with working pressures from 10 to 690 bar and pipe diameters between 16 and 600 mm.

How do they fit into the integrated system?

GS components are part of the integrated rigid system and, together with the adapters, complete the range of rigid connections available. This is a very important concept, because it means fully realizing how different components interact together within a single system. It also means accumulating experience that can then be returned to customers, supporting them in their choices at best. This is the only way to be one single provider.

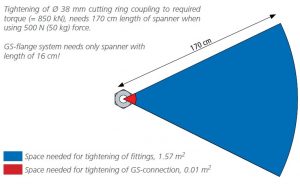

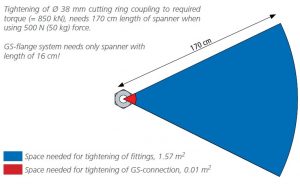

While adapters allow us to ensure the connection of rigid pipes since smallest diameters, GS flanged connections give us the opportunity to connect bigger pipes, returning benefits already from the Ø25 mm and thus reducing the tightening force required for the operator, the installation space and the weight of the system, without compromising its safety.

How does the GS-Hydro brand take part in the Interpump Fluid Solutions offer?

Interpump Fluid Solutions represents the synthesis of the concept of integrated system within which coexist different brands and products. Among these, the GS Hydro brand and its GS Components have a history of over 40 years. We are talking about the world’s leading supplier of non-welded piping systems; operations began in 1974 with the commercialization of an innovative flange, which allowed the rapid and secure connection of pipes without the need for welding. This technology, applied to the non-welded connection concept, has expanded over time and has been validated in thousands of applications for over four decades and has been taken to virtually every corner of the globe.

Tell us about one of the most challenging projects you have undertaken with your team.

Did you know that we participated in the construction of the largest vessel in the world? We made a pipeline system, by our GS-Hydro flanged connections, through the full-width of vessel (over 100 meters). A challenge never faced before: the waves power, the temperature gradient and pressure rating have challenged the solidity of our GS-Hydro components, certificated by Lloyds. Standard products could not be applied to such a particular structure, and it wasn’t easy, but finally we designed and built a customized piping system able to face the hostility of seas.

What is the strength of your team?

Our strength, reflecting our shared business values, is to be able to create tailor-made solutions, according to the needs of the customer. Products not standardized but designed for specific applications together with our specialist team.

My task within the department is to organise and manage the tests and maintenance of the test machines, working closely with the engineer V. Ciarelli, head of the department, and support my colleagues, Nicola and Sandro.

My task within the department is to organise and manage the tests and maintenance of the test machines, working closely with the engineer V. Ciarelli, head of the department, and support my colleagues, Nicola and Sandro.

Our core business is certainly the production of hoses, but our offer is much wider: fittings, adapters, machines and of course the flanges that we’re talking about today. Thanks to

Our core business is certainly the production of hoses, but our offer is much wider: fittings, adapters, machines and of course the flanges that we’re talking about today. Thanks to